Step 2: Selection of the formed wire material Issues such as the length and diameter of the formed wires are highlighted at this stage. This is done keeping in mind the application area of the formed wires.Īll the dimensions and configurations for the wire are laid down at this stage of production. The requirement specifications for the formed wires are laid down at this stage of production. Otherwise, here are the steps that are followed when producing formed wires: Step 1: Design specification Formed wires manufacturers use special machines that are designed for the mass production of formed wires. The final formed wires that we see in the market are products of well-curated plans and procedures. The choice of the formed wire material will solely depend on your area of application or what you intend to use the wire for. The most common ones include stainless steel, carbon steel, brass, copper, zinc, and other alloys. There is also a variation of the lengths for the formed wires.Īfter the conventional manufacturing process, formed wires undergo further post-manufacturing procedures that are designed to boost their strength and protect them from both physical and chemical damage.Īlso, it is important to note that formed wires are made from strong materials. Some formed wires are thick while others are thin. They are also customized to have different sizes and dimensions. The wire spools can be configured into any shape and form depending on the intended area of application. This is a process in which wire spools are designed shaped and configured to have certain specifications.

These are wires that have been manufactured from the wire forming process.

We are going to look at some of these wires and at the end of it all, you will be able to choose the best formed wires. Planning to buy formed wires for your transmission line project? It is prudent to ensure that you not only buy the wire but also the right one that will perfectly meet your needs. There are different types of support mechanisms that are used for holding conductors or even when joining conductors. You will find it necessary to ensure that the conductors are properly attached to their positions. We also manufacture products according to the customers’ specifications.Īfter the installation of conductors on transmission lines, the process does not stop there. Once you know the kind of action that is needed in your installation, you will pick the appropriate formed wire from the above list. Insulator tie (top tie, side tie, and spool tie)Įach of the formed wires plays a unique role in a utility.

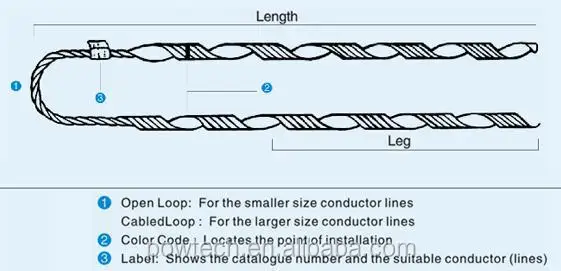

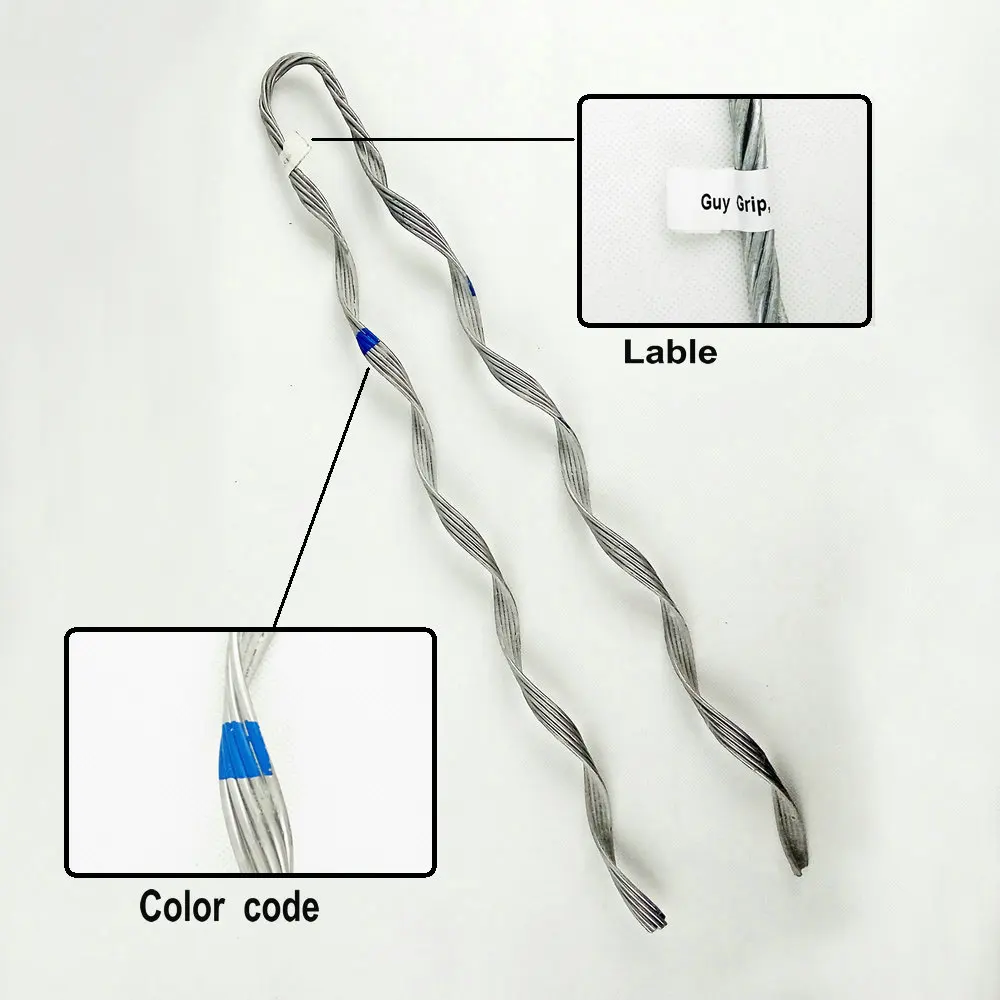

#Guy wire preform color code iso

Regardless of the role, you should strive to get the best-formed wires that will perfectly fit its job description.Īs an ISO certified manufacturer and supplier, Jingyoung can supply you types of the formed wires: Others are used when you want to join the conductor cables. Some of the formed wires ensure that the conductors remain stable in their respective positions. It is hard to underestimate the important roles that the formed wires play in any utility and installation. Formed Wire is also called preformed line, Jingyoung has all classes of formed wires that meet your electrical and telecommunication utility needs.

0 kommentar(er)

0 kommentar(er)